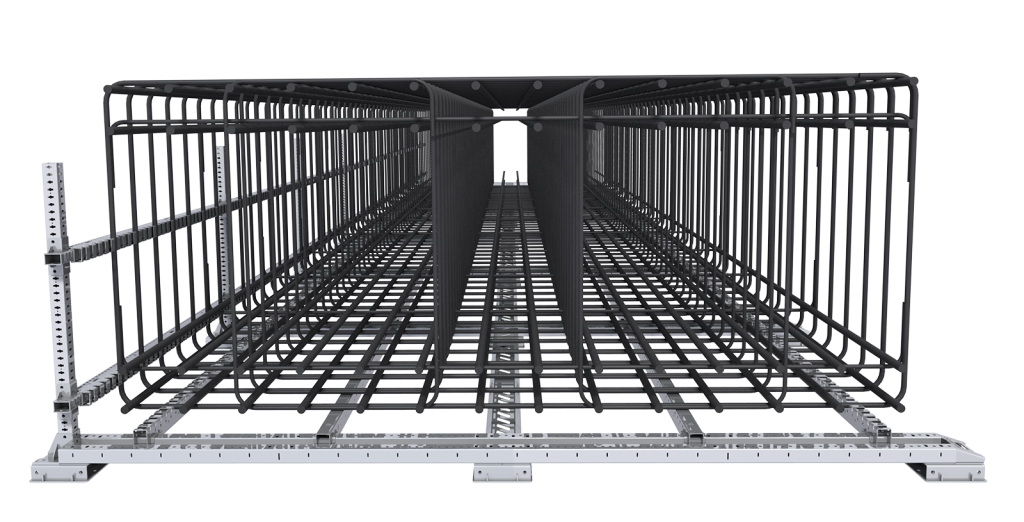

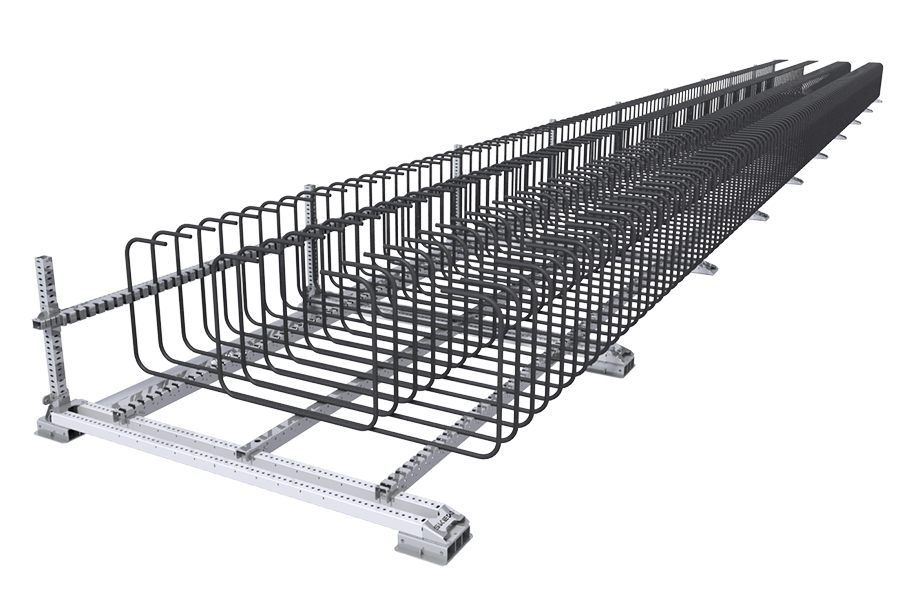

Meet our reinforced Heavy Duty JIG, a modular JIG System, designed for larger and heavier reinforcement cage fabrication.

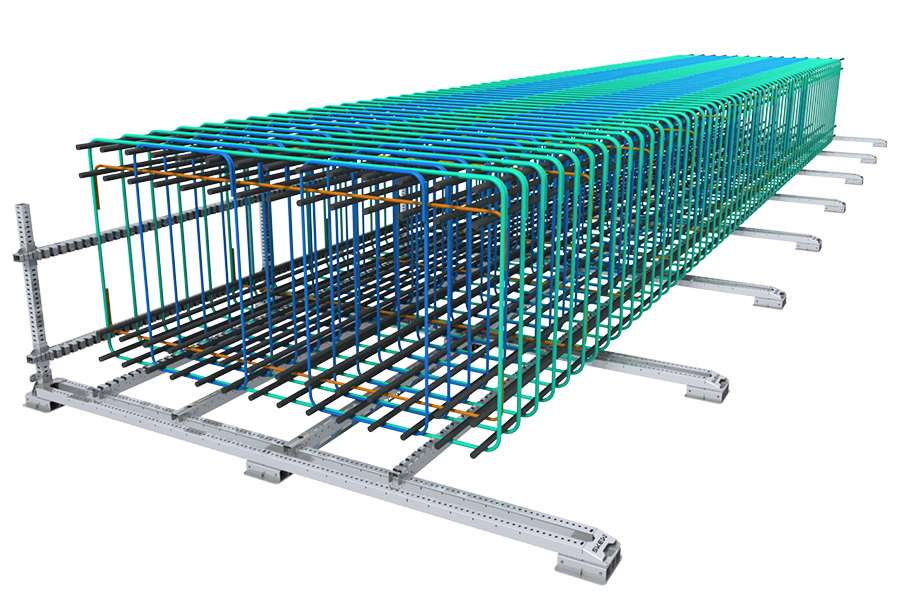

Examples:

Modular Platform

The SKEW Engineers can customize and enhance this JIG platform for your heavier reinforcement meshes. We can include splice areas, double bar gripping locations and supports for couplers, inserts etc.

With a maximum load capacity of +500kg/m2, this JIG System is ideal for heavy bars ranging from diameter 10 to 40mm.

Standard with a 50mm stirrup / rebar spacing

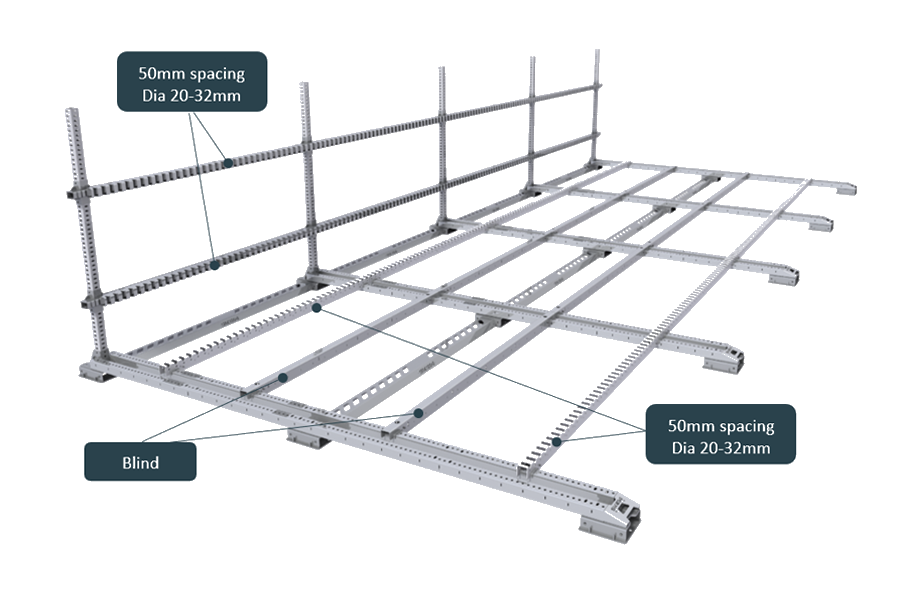

Example JIG:

- 7.2 x 3.0m Working area

- 15cm working height

- 4 Rows of teeth for rebar diameter 20-32 @50mm spacings.

- Additional 2 support profiles

- 1.4m Backing

- Expandable with 1.8m sections

Fast JIG build-up: within a single day

Constructed from 1.8-meter modular sections, the system is designed for a fast and efficient setup. For example, a 60-meter JIG system can be assembled by just two workers in a single day. This rapid construction means that once your floor space is ready, you can start manufacturing the very next day.

The JIG system is highly adaptable, allowing you to easily adjust it to accommodate variations in reinforcement throughout a project. It also provides the flexibility to quickly change over the JIG for any last-minute design revisions.

Work Safe, Work Smart

Stable Working Platform: Provides a secure and stable environment for handling heavy materials, reducing the risk of accidents and injuries associated with manual rebar assembly.

Reduced Physical Strain: The JIG supports the weight of the rebar during assembly, reducing physical strain and fatigue on workers and minimizing the risk of back injuries.

Proven: A homemade rebar jig can be safe if designed, built, and used correctly, but it inherently carries more risk than a professionally engineered JIG system like the SKEW JIG System

“Although we ordered the SKEW JIGs specifically for the quality control and process efficiency, the jigs have been fantastic from a safety perspective. SKEW designed and manufactured the jigs to cater of various lengths, widths, and reinforcement cage weights, they provide a solid robust base which eliminates any risk of overturning”. – Mark Booth, Health and Safety Advisor