Reinforced concrete (RC) beams are fundamental to construction, masterfully combining concrete’s strength in compression with the tension resistance provided by steel rebar. To meet diverse structural needs, beams are designed with many support conditions (like Simply Supported or Continuous) and cross-sections (like Rectangular or T-Beams).

Modern construction dramatically speeds up projects by moving key manufacturing steps off-site to produce three primary product groups:

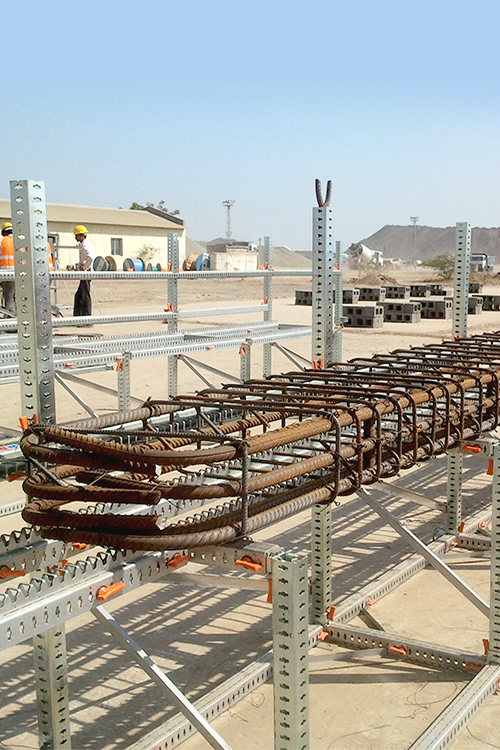

1. Prefabricated Reinforcement Cages

This is the steel skeleton of the beam—the rebar assembly alone. Built with precision off-site, using tools like the SKEW JIG System, the completed cage is transported to the construction site. The cage consists of longitudinal (main) rebar held together by stirrups (or links) that resist shear forces.

These stirrups often require varying spacings along the beam’s length, making the precise placement on the JIG System absolutely crucial for a high-quality output.

This method is ideal for elements like Foundation Beams, Ground Beams, Capping Beams, Abutment Beams, and Bridge Beams. Once delivered, the cage is placed into temporary formwork, and the liquid concrete is poured and cured around it (cast-in-situ).

2. Precast Concrete Beams

The Precast Concrete Beam is the final, solid concrete element itself, manufactured entirely in a controlled factory.

The rebar cage—complete with accurately placed stirrups—is set inside a reusable mould where concrete is poured, vibrated, and cured. The finished, hardened beam—including standard Rectangular Beams, T-Beams, Bridge Beams, Box Beams, and U-beams—is then shipped to the site and lifted directly into place, ready for immediate installation.

3. Prestressed Concrete Beams

The most specialized product is the Prestressed Concrete Beam, a high-performance variant of a precast beam. Its distinguishing feature is the use of high-strength steel tendons that are intentionally tensioned—either before the concrete cures (pre-tensioning) or after (post-tensioning).

This process subjects the beam to active compression, drastically improving its resistance to cracking and allowing for much longer spans and slimmer cross-sections.

This structural efficiency saves cost by reducing material use and minimizing the need for intermediate supports and columns.

The Role of Precision Fabrication

The SKEW JIG System plays a critical role in supporting the fabrication of the steel core for all three product types. This modular and adjustable workbench ensures the precise tying and welding of rebar, including the accurate placement of stirrups at varying intervals. This precision guarantees perfect bar spacing and concrete cover, which is essential for the durability of the final element. Its ability to quickly adapt to various lengths, heights, and skew angles maximizes both efficiency and quality control across the full range of modern RC beam production.