The SKEW JIG System – Table JIG provides extensive flexibility to produce special mesh panels.

In addition to the mesh welding machines, or cutting mesh from sheets, the SKEW JIG System can be used to weld/tie mesh panels from individual bars.

We offer extensive flexibility in rebar diameters combinations, mesh spacings, and overall dimensions.

On the SKEW JIG System the bars can be placed on a predetermined grid, prior to welding or tying by hand or even by welding robot.

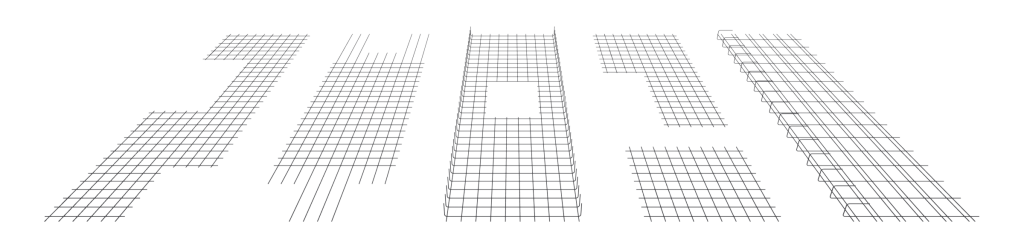

Mesh on the Table JIG:

The Table Setup is suitable for fabricating complex rebar mesh panels. Unlike automated machines, its adjustable components can handle variable bar dimensions rebar shapes and combinations, making it ideal for custom or intricate designs. This system is crucial for creating high quality mesh panels that are otherwise difficult or impossible to make.

Mesh on the Floor JIG System

The SKEW JIG System’s floor setup is ideal for assembling large mesh panels with precise (parallel) placement, essential for custom designs. It securely holds the bars, including fiberglass and basalt reinforcement, ensuring accurate 25 or 50mm spacing, and improving assembly speed.

Heavy Mesh JIG System

A unique adjustable JIG platform, designed to support the reinforcement in the desirable rebar diameters and spacing for large and heavy mesh panels.

Suitable JIG Systems:

Both the Table Setup and Floor Setup can be equipped with reinforcement grips in two directions. Additionally, the first and second layer reinforcement orientation can be swapped, if necessary.