Diverse Materials, One Reinforcement Assembly Solution

The construction industry is moving beyond standard carbon steel, adopting a variety of specialized reinforcement materials to combat corrosion and meet complex design needs. This shift is crucial for long-lasting infrastructure but presents a major fabrication challenge, as most automated machinery is only designed for standard rebar.

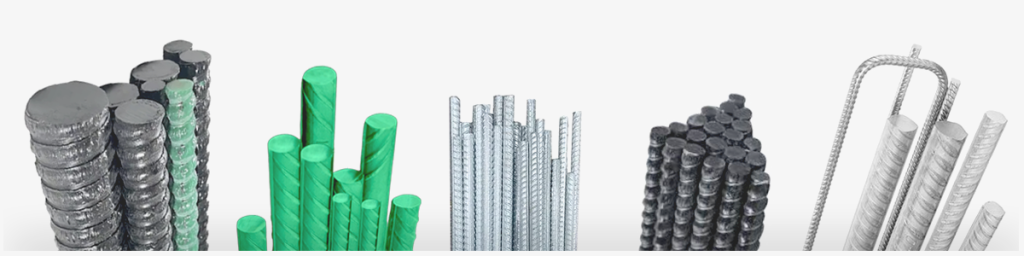

Modern construction utilizes a wide spectrum of reinforcement, each with unique properties and assembly requirements:

Corrosion-Resistant Metals:

- Galvanized and Epoxy-Coated Rebar provide resistance to salts and moisture, but their protective layers are easily damaged by automated steel processors.

- Stainless Steel offers the highest corrosion resistance for the harshest environments, but its cost demands precision fabrication.

- Fiber-Reinforced Polymers (FRP): Glass Fiber (GFRP) and Basalt Fiber (BFRP) are lightweight, non-conductive, and completely immune to rust. They require custom, non-destructive assembly since they cannot be bent on site.

The Flexible Fabrication Solution: The SKEW JIG System

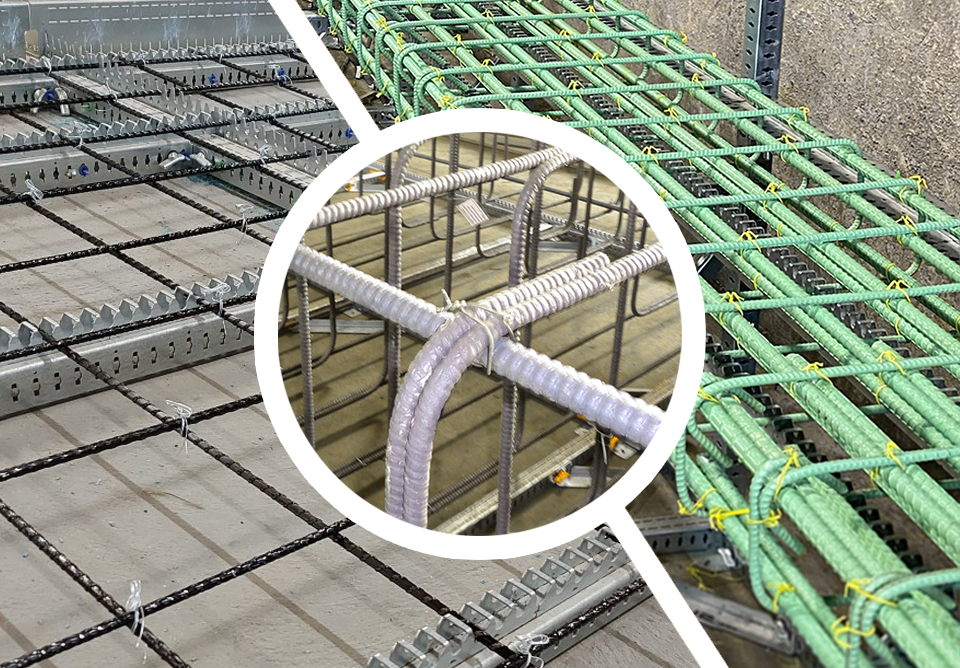

When specialized reinforcement cannot be economically prefabricated by standard machinery, a flexible assembly platform is essential. The SKEW JIG System is a modular workbench designed to solve this fabrication dilemma for all reinforcement types.

On top when traditional tying wire, or welding is not allowed, alternative fastening methods are often considered.

The JIG System converts manual assembly into a high-precision, industrial process. It handles any reinforcement material (GFRP, stainless steel, etc.) without damaging coatings, quickly builds complex or skewed custom cages with guaranteed accuracy, and eliminates waste from single-use wooden jigs for superior efficiency and quality.

The SKEW JIG System ensures that the benefits of diverse reinforcement materials, from superior corrosion resistance to non-conductivity reinforcement.

There are other reasons for alternative reinforcements to be used. In this case (GFRP rebar) is used in the “soft-eye” section of a diaphragm wall is to ensure cuttability for Tunnel Boring Machines (TBMs).

Unlike traditional steel rebar, GFRP can be easily and quickly crushed by the TBM’s cutter head, allowing the machine to break through the wall without stopping to perform a difficult and time-consuming dismantling operation. This process saves significant time and cost in tunneling projects, while the GFRP still provides the necessary temporary structural support to the wall.

Again, the SKEW JIG System allows fast and precise assembly of these GFRP reinforcement cages.