The construction industry has long faced a challenge with rebar mesh fabrication. Traditional methods are limited in two main ways. First, automated mesh welding machines struggle with thicker, larger diameter rebars, as the coiled input is difficult to straighten and manipulate. Second, manual assembly is physically demanding, leading to low efficiency, high labour costs, and significant safety risks for workers. Handling heavy rebar increases the chance of injuries, especially to the back.

The Rise of Robotics in Rebar Fabrication

Robotic welding and placement are a powerful solution to these limitations. Robots can effortlessly and precisely handle large-diameter rebar, automating the entire process from cutting and bending to placement and welding. Unlike humans, robots can work continuously without fatigue, ensuring consistent quality and a high degree of accuracy. They also operate safely in hazardous environments, reducing risks for human workers. By adopting automation, companies can streamline their fabrication process, boost productivity, and lower long-term labour costs.

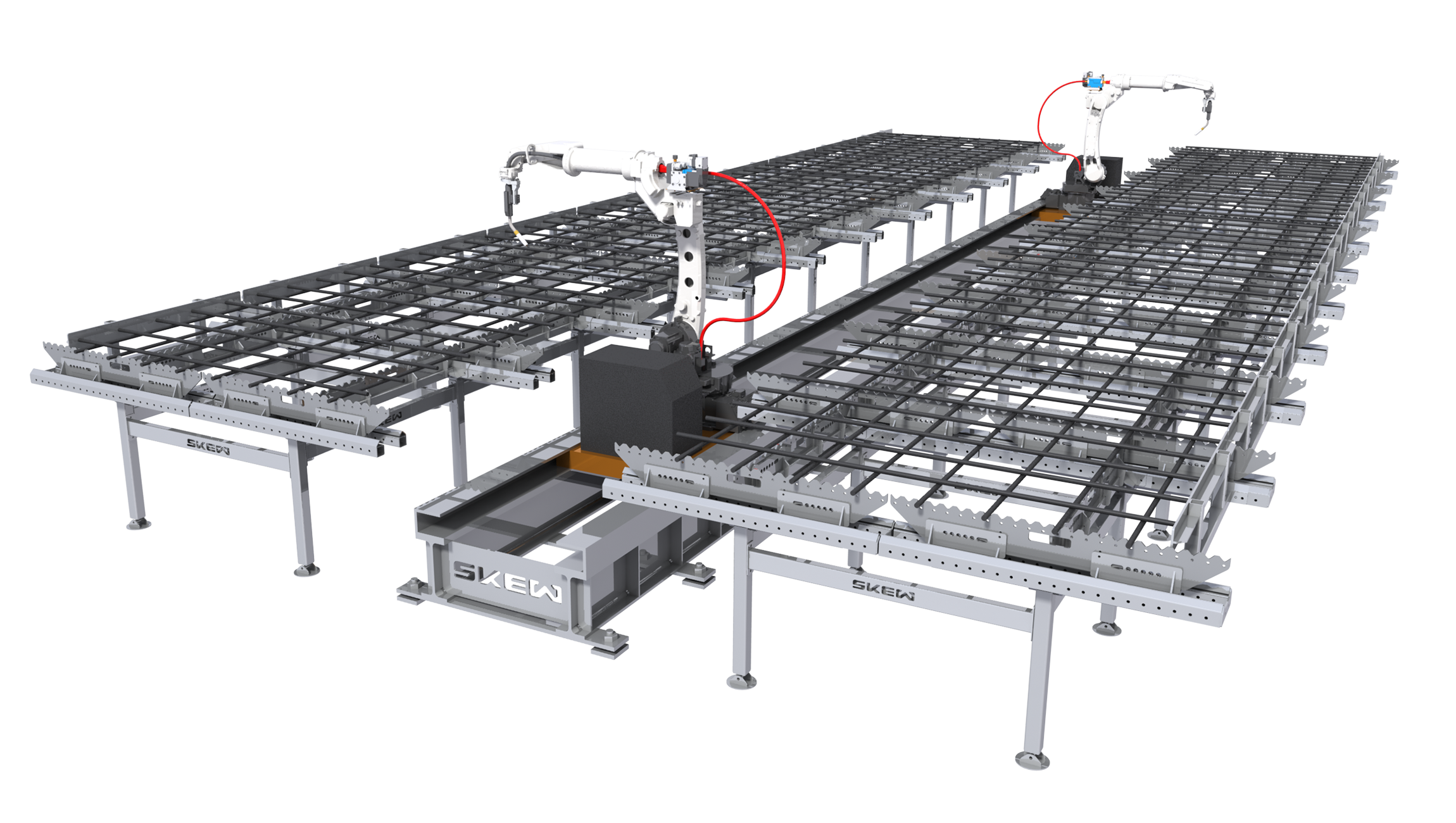

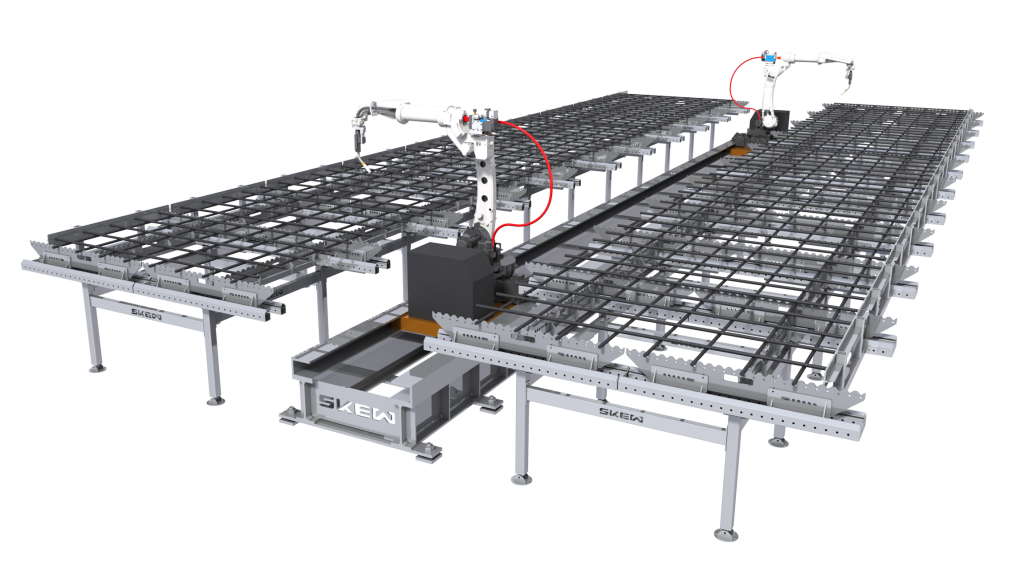

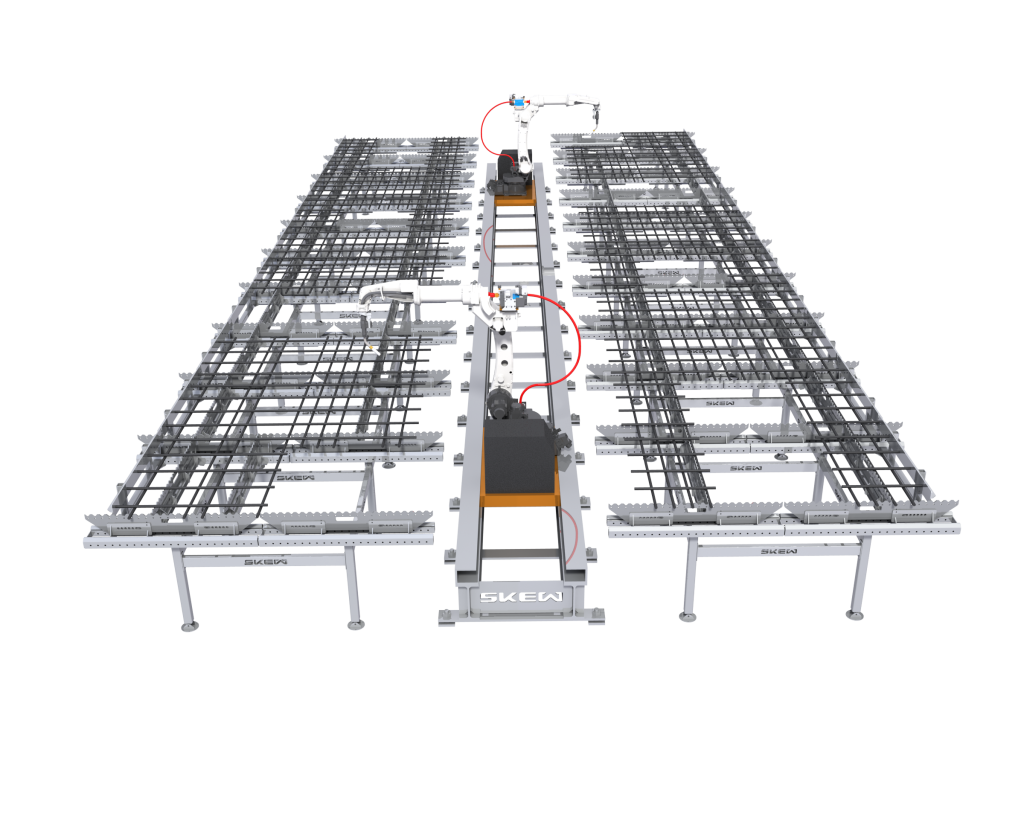

SKEW’s Innovative JIG System

Recognizing the need for better hardware to support robotic fabrication, SKEW is developing a new JIG system specifically for robotic operation. This innovative system is designed to handle the demands of large and heavy meshes with minimal human intervention.

The key features of SKEW’s new JIG system include:

- Modular and Adaptable Design: The system can be quickly adjusted to accommodate different rebar sizes and configurations.

- Precise Placement: It ensures the exact placement of rebar with a predetermined mesh zero-point between bar layers.

- Versatile: The system is adaptable for rebars with diameters ranging from 20 to 40mm.

- Reduced Human Intervention: The new design allows a single operator to oversee multiple robotic welding cells, minimizing the need for direct human interaction.

SKEW believes that by addressing this fundamental hardware challenge, they can unlock the full potential of robotic rebar welding. This initiative highlights a crucial lesson: achieving true automation means rethinking the entire process, not just replacing one component.

SKEW has a wide network of partners to support the implementation of these JIG systems. You can contact their team to connect with suppliers of robots specifically designed for reinforcement welding and tying.